When it comes to construction, the choice of building materials can significantly impact the outcome of a project. Bricks, in particular, have been a cornerstone in construction for centuries due to their durability, longevity, and fire-resistant properties.

However, not all bricks are created equal, and understanding the characteristics of different types is crucial for any builder or DIY enthusiast. In this comprehensive guide, we will explore in-depth the seven types of bricks that everyone in the construction realm should be familiar with.

Whether you’re working on a small backyard project or a large-scale structural endeavour, this guide from Build it Gansbaai aims to provide the knowledge you need to make informed decisions for your next construction masterpiece.

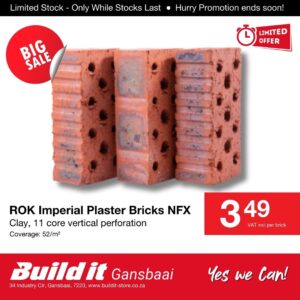

1. Burnt Clay Bricks

Overview:

Burnt clay bricks, also known as common bricks, stand as the most abundant type in modern construction. They find application in columns, walls, foundations, and various other purposes.

These bricks are versatile but require plastering or rendering with mortar to enhance their strength, water resistance, and insulating ability when used in walls.

Classifications:

Burnt clay bricks are categorized into four classes based on quality. Fourth-class bricks are over-burnt and irregular, often used as aggregate.

Third-class bricks are of poor quality and suitable only for temporary structures. Second-class bricks, though of moderate quality, have an irregular shape and rough surface.

The best quality is found in first-class bricks, which have a standard shape, smooth surface, and enhanced durability and strength.

Best For:

The versatility of burnt clay bricks makes them suitable for a variety of construction purposes, making them the most commonly used bricks in modern construction.

2. Sun-Dried Clay Bricks

Overview:

Sun-dried clay bricks harken back to ancient construction methods, with origins dating as far back as 7,000 BC. Made from a mixture of loamy soil, water, and straw, these bricks might also include manure, clay, or sand for added strength.

They are formed by pouring the mixture into moulds and drying them in a location protected from rain.

Strength and Use:

While sun-dried clay bricks are the least durable of brick types, they offer an affordable and DIY-friendly option for temporary structures.

However, caution is advised, and they should never be used as load bearing supports or foundations due to their relatively weak structure.

Best For:

Sun-dried clay bricks are a cost-effective choice for temporary DIY structures, offering an authentic and historical touch to certain projects.

3. Concrete Bricks

Overview:

Concrete bricks, made from solid concrete, are a popular choice for internal brickwork, facades, and fences.

They can be manufactured on-site with a standard mix of one part cement, two parts sand, and four parts aggregates. Adjusting the formula can result in increased strength for foundation use.

Customization:

Manufacturers can create concrete bricks in various sizes and shapes by pouring concrete into custom moulds.

Professionals on-site can also produce them with the right mix, saving time and reducing costs for larger construction projects.

Best For:

Concrete bricks are commonly used for facades, internal brickwork, and outdoor walls. They are practical for both professional masons and DIYers, offering versatility and cost-effectiveness.

4. Engineering Bricks

Overview:

Engineering bricks are a favourite among structural engineers due to their high compressive strength and density, making them ideal for load-bearing structures.

With low absorption capacity, these bricks resist moisture, preventing cracks, crumbling, or leakage.

Resistance and Applications:

The low porosity of engineering bricks also makes them resistant to chemicals that might damage other types of bricks. Consequently, they are regularly used in basement foundations, sewers, manholes, and retaining walls.

Best For:

Ideal for load-bearing structures, engineering bricks find their home in basements and other critical applications where strength and resistance to moisture and chemicals are paramount.

5. Sand Lime Bricks

Overview:

Sand lime bricks, made from a mixture of sand, lime, and sometimes colour pigments, offer high compressive strength. These bricks are commonly used for load-bearing walls due to their smooth finish and uniform appearance.

Mix and Finish:

Manufactured using heat and pressure to accelerate the chemical reaction, sand lime bricks require less mortar plaster, saving time and costs on projects.

Additionally, their dense composition makes them a popular choice for acoustic insulation.

Best For:

Sand lime bricks excel in load-bearing walls and acoustic insulation projects. Their high strength and fire resistance contribute to their popularity in construction.

6. Fly Ash Bricks

Overview:

Fly ash bricks are a sustainable alternative to traditional burnt clay bricks, as they are made using class C or class F fly ash—a byproduct of coal-fired power plants. This not only reduces environmental impact but also helps reuse toxic metals found in fly ash.

Compressive Strength and Size:

These bricks exhibit high compressive strength and low water absorption, making them an excellent substitute for burnt clay bricks. However, their durability decreases with size, so they are generally available in smaller dimensions.

Best For:

Fly ash bricks are a strong and durable choice for construction, offering an environmentally friendly option by reusing materials from coal-fired power plants.

7. Firebricks

Overview:

Firebricks, also known as refractory bricks, are specially designed to withstand extreme temperatures.

Made with fireclay, these bricks contain high levels of silica and alumina, enabling them to endure temperatures greater than 3,000 degrees.

Heat Resistance and Applications:

Firebricks are not just resistant to flames but also to low temperatures and rapid temperature changes.

These properties make them perfect for applications such as lining chimneys, building brick grills, fire pits, wood-fired ovens, and any other project requiring high-heat resistance.

Best For:

Commonly used in projects involving intense heat, firebricks guarantee structural integrity under extreme temperature conditions.

How To Calculate Quantities

Quantity estimation of materials depends on the mix proportions of the concrete and is essentially required in any construction works. Let’s get started with the discussion of how to calculate bricks, cement, and sand in brick masonry.

Assuming,

- Volume of brickwork = 1 m3

- Grade of mortar = 1:6 (cement: sand)

- First class brick (190 mm x 90 mm x 90 mm)

- Thickness of mortar = 10 mm = 0.01 m

No. Of Bricks:

No. of bricks = (Volume of brickwork / Volume of one brick with mortar)

Volume of one brick without mortar = 0.19×0.09×0.09 = 0.001539 m3

Volume of brick with mortar = (0.19+0.01) x (0.09+0.1) x (0.09+0.1)

= 0.2×0.1×0.1 = 0.002 m3

No. of bricks = 1.0/ (0.002) = 500

Consider 10% to 15 % bricks as wastage.

∴ Total no. of bricks = 500 + (10 x 500)/100 = 550

Quantity Of Mortar:

Volume occupied by bricks = No. of bricks x Volume of one brick

Volume of bricks = 500 x 0.001539 = 0.7695 m3

Volume of mortar = Volume of brickwork – Volume of bricks

∴ Volume of Mortar = 1.0 – 0.7695 = 0.2305 m3

Quantity Of Cement:

Cement = (Dry volume of mortar x Cement ratio)/ Sum of the ratio

Dry volume of Mortar = 1.54 x 0.2305 = 0.35497 m3 (54% increment due to volume shrink after adding water)

Cement= (0.35497 x 1) / (1+6) = 0.35497/7= 0.05071 m3

Cement = 0.043795 x 1440 = 73.0224 kg

∴ No. of cement bags = 73.0224 / 50 = 1.45 bags (1 bag cement contains 50 kg cement)

Quantity of Sand:

Sand = (Dry volume of mortar x Sand ratio)/Sum of the ratio

Sand = (0.35497 x 6)/7 = 2.12982/7 = 0.30426 m3

∴ Sand = 0.30426 x 35.3147 = 10.7448 cft.

Summery:

Number of Bricks = 550

Cement = 1.45 bags of 50 Kg

Sand = 0.30426 m3 or 10.7448 cft.

Understanding the intricacies of these seven types of bricks is crucial for anyone involved in construction.

Each type has its unique properties and applications, and choosing the right one can make a significant difference in the success of a project.

Whether you’re a professional builder or a DIY enthusiast, Build it Gansbaai is your partner in providing high-quality building materials for your next construction venture.

Visit our store today for expert advice, top-notch materials, and the tools you need to turn your vision into a lasting reality.

Build with confidence, build with Build it Gansbaai.

Or log on to our online store, and shop from the comfort of your home: www.buildit-store.co.za

Follow us on social media, to stay up to date with our latest sizzling specials and promotional offers!

Build it Gansbaai offers added value services in respect of hardware retailing; embracing all activity within the building materials industry, focusing specifically on the building of; urban, township, rural housing as well as all home improvements and do it yourself.